Popular Products

Performance Products

PTFE Standard Tubing - All Sizes

Description This is the original fluoropolymer. Great in a wide range of applications from electrical wire insulators, fluid flow tubing, medical d...

View full details

FEP Standard Tubing - All Sizes

Description The properties of FEP tubing drives its use in many applications that require high electrical breakdown voltage, low dielectric const...

View full details

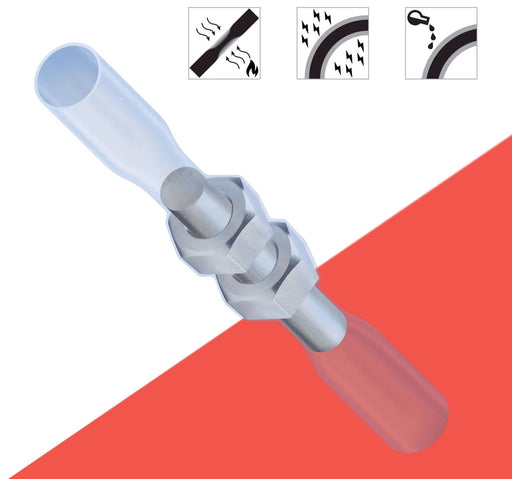

FEP 1.3X Fractional and AWG Heat Shrink Tubing

Description FEP 1.3:1 heat-shrink tubing is a great choice for insulation, encapsulation, and wire harness of components like medical instruments, ...

View full details

PVDF Standard Tubing

Description PVDF tubing is a stronger, more abrasion resistant material than its per-fluorinated (all Carbon-Fluorine – CF2) counterparts such as P...

View full details

FEP Sheets (12" x 12")

Description FEP is used for its high temperature (ability to handle live steam up to 30 psig) low friction properties, and wide-ranging chemical re...

View full details

PFA Sheets (12" x 12")

Description PFA is a modified version of PTFE, except it is optically clear and has a higher tensile strength. Similar to PTFE and FEP, PFA exhibit...

View full details

PVDF Standard Tubing

Description PVDF tubing is a stronger, more abrasion resistant material than its per-fluorinated (all Carbon-Fluorine – CF2) counterparts such as P...

View full details

FEP Retractable Coil

Description Organize your work area with self-retracting FEP coils that extend when you need them and retract when you don't. They are compatible w...

View full detailsStore News

High-Purity Fluid Systems: Why Fluoropolymer Tubing is Critical for Cleanroom and Semiconductor Applications

High-purity fluid systems are a cornerstone of advanced manufacturing processes across multiple industries, ensuring clean, reliable, and contamination-free fluid transfer. Whether you are operating a semiconductor fab, a pharmaceutical cleanroom, or a laboratory, investing in the right high-purity tubing and system design can safeguard your processes, protect your products, and ensure compliance with stringent industry standards.

Application Spotlight: Fluoropolymers use in home healthcare

As home healthcare becomes a cornerstone of modern medicine, fluoropolymer tubing is a vital component enabling safer, more reliable, and more comfortable patient care. By leveraging PTFE, PFA, and FEP tubing in device design, manufacturers can meet the evolving demands of home healthcare while ensuring patient safety and regulatory compliance.

Fun in the Sun: The Hidden Fluoropolymers Behind Your Summer Adventures

While we might not make swimsuits or sunglasses, Fluorotherm’s products support industries that make summer better—from beverage production and pool chemicals to portable gear manufacturing. So the next time you’re enjoying a sunny day, give a little thanks to the high-performance materials working behind the scenes.