Popular Products

Performance Products

PTFE Standard Tubing - All Sizes

Description This is the original fluoropolymer. Great in a wide range of applications from electrical wire insulators, fluid flow tubing, medical d...

View full details

FEP Standard Tubing - All Sizes

Description The properties of FEP tubing drives its use in many applications that require high electrical breakdown voltage, low dielectric const...

View full details

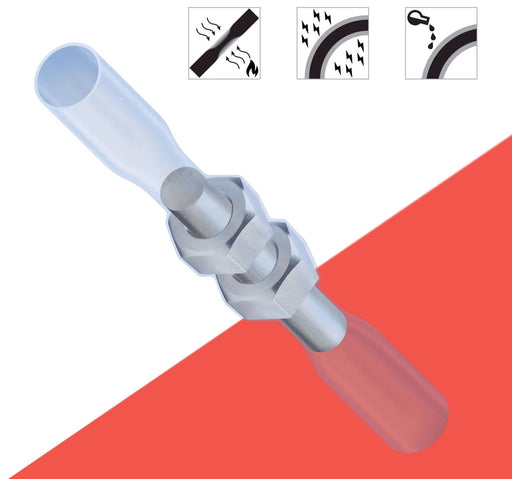

FEP 1.3X Fractional and AWG Heat Shrink Tubing

Description FEP 1.3:1 heat-shrink tubing is a great choice for insulation, encapsulation, and wire harness of components like medical instruments, ...

View full details

PVDF Standard Tubing

Description PVDF tubing is a stronger, more abrasion resistant material than its per-fluorinated (all Carbon-Fluorine – CF2) counterparts such as P...

View full details

PVDF Standard Tubing

Description PVDF tubing is a stronger, more abrasion resistant material than its per-fluorinated (all Carbon-Fluorine – CF2) counterparts such as P...

View full details

PTFE 6-Foot Custom Lengths

Description PTFE thick-walled straight lengths come in 6-foot sizes and possess the same properties as standard PTFE. They are a great choice as a...

View full details

H2 PFA Thermally Conductive / Anti-Stat Tubing

Description A proprietary material, H2 PFA tubing from Fluorotherm has almost 3x higher heat conductivity than standard PFA. It can be used in a va...

View full details

H2 FEP Thermally Conductive / Anti-Stat Tubing

Description A proprietary material, H2 FEP tubing from Fluorotherm has almost 3x higher heat conductivity than standard FEP. It can be used in a va...

View full detailsStore News

Are you preparing for the changes to USP Class VI testing?

The conversation around USP Class VI is not about eliminating standards but about elevating them—moving toward approaches that are scientifically rigorous, globally consistent, and ethically responsible. Whether this shift happens quickly or gradually, it reflects a broader industry trend: the continuous re-examination of how we define and demonstrate safety.

Clean Water in Every Season: Fluoropolymers in Fall Environmental Monitoring

Whether in autumn or any other season, environmental scientists and municipal water authorities depend on materials that deliver consistent, reliable results. Fluoropolymers ensure that every test, from groundwater wells to surface water surveys, provides accurate data for protecting communities and ecosystems.

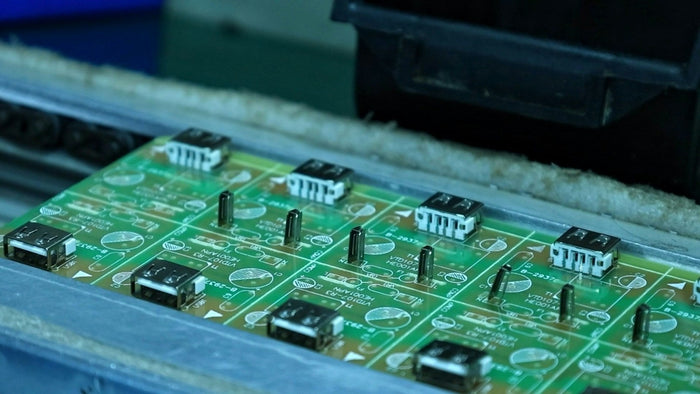

High-Purity Fluid Systems: Why Fluoropolymer Tubing is Critical for Cleanroom and Semiconductor Applications

High-purity fluid systems are a cornerstone of advanced manufacturing processes across multiple industries, ensuring clean, reliable, and contamination-free fluid transfer. Whether you are operating a semiconductor fab, a pharmaceutical cleanroom, or a laboratory, investing in the right high-purity tubing and system design can safeguard your processes, protect your products, and ensure compliance with stringent industry standards.