Fluoropolymer Heat Exchangers: Versatile, High Performance, and Game-changing

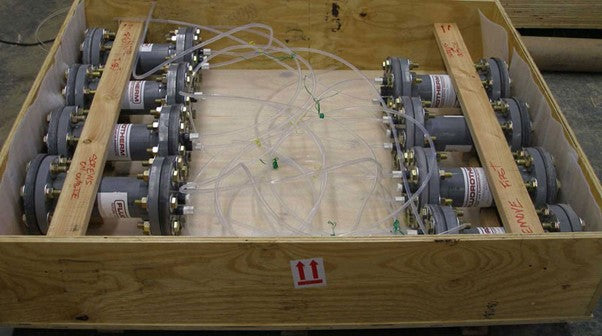

Fluorotherm shell and tube heat exchangers are used to transfer heat between two fluids. They are commonly used in applications where one fluid needs to be heated or cooled in a controlled environment, such as in chemical processing or pharmaceutical manufacturing. These devices are constructed from highly durable fluoropolymer materials and designed to be easily dissembled for cleaning, maintenance, and inspection.

Shell and tube heat exchangers are a versatile technology designed for efficient heat exchange in a safe and controlled manner. Let’s take moment to learn about these devices, how they work, what they are made from, and in which industries they’re currently used.

What is a Shell and Tube Heat Exchanger

A shell and tube heat exchanger is a device used to transfer heat between two fluids. The device is made of a series of tubes placed inside a larger shell. One fluid runs through the tubes while the other fluid flows around the outside of the tubes in the shell. As the two fluids come into contact with each other, heat is transferred from one fluid to the other.

Shell and tube heat exchangers are commonly used in a variety of industries, including petrochemical processing, pharmaceutical manufacturing, and food and beverage production. These devices are often used to heat or cool one fluid in a controlled environment while the other fluid remains at ambient temperature.

What are Heat Exchangers Made From

Shell and tube heat exchangers are made from a variety of materials, including metals such as stainless steel, copper, and aluminum, as well as chemically inert fluoropolymers such as PTFE and FEP. These materials are selected based on the compatibility with the fluids being used, the operating conditions, and the desired level of performance.

What are the Advantages

Shell and tube heat exchangers offer a number of advantages over other types of heat exchangers, making them an essential tool in many chemical processing plants. These advantages include:

- Ease of cleaning and inspection – Shell and tube heat exchangers can be easily dissembled for cleaning and maintenance. This allows for a more thorough cleaning of the device, which is often necessary for applications where sanitary conditions are required or when safety is a concern.

- Durability – Shell and tube heat exchangers are constructed from durable materials that can withstand a variety of operating conditions, including variable temperatures and exposure to caustic compounds.

- Versatility – Shell and tube heat exchangers are available in a wide range of sizes and configurations to suit a variety of applications, including industrial-scale processing.

Without these technologies, many of the products we rely on every day would not be possible. For example, we would not be able to easily produce petrochemicals used to make plastics, nor would we be able to manufacture certain pharmaceuticals we take to keep us healthy.

Final Thoughts

Shell and tube heat exchangers are essential pieces of equipment in many industrial settings. By transferring heat between two fluids in a controlled environment, these devices play an essential role in the manufacturing of many everyday items. And, thanks to the durable materials used to create shell and tube heat exchangers, they can withstand most conditions.