Have you thoroughly protected and insulated your electrical components?

Are you looking for a skin-tight sheath over your components to protect and insulate them effectively?

FEP heat-shrink tubing could be the perfect solution. It offers a practical means of insulating electrical and mechanical parts, especially where the higher operating temperatures of other materials like PFA are not required. It's also non-flammable, inert to corrosive chemicals, resistant to weathering, has a very low coefficient of friction and great anti-stick properties. After it shrinks to the desired size, it retains its transparency, so you can easily read any printed label on the protected component.

Key Benefits of FEP heat-shrink tubing

- A lower shrink temperature allows it to be used to protect more components that get damaged from high temperature

- Transparency enables clear identification of protected components and label visibility

- Since FEP melts, it is heat-sealable

- Available in AWG, standard sizes and roll and probe covers

Fluorostore offers several types of heat-shrink tubing products, from 1:3 shrink ratio standard and AWG sizes to probe and roll covers, all made from FEP. You can generally cover any square, rectangular, and irregular shapes with heat-shrink tubing.

How to pick the correct size

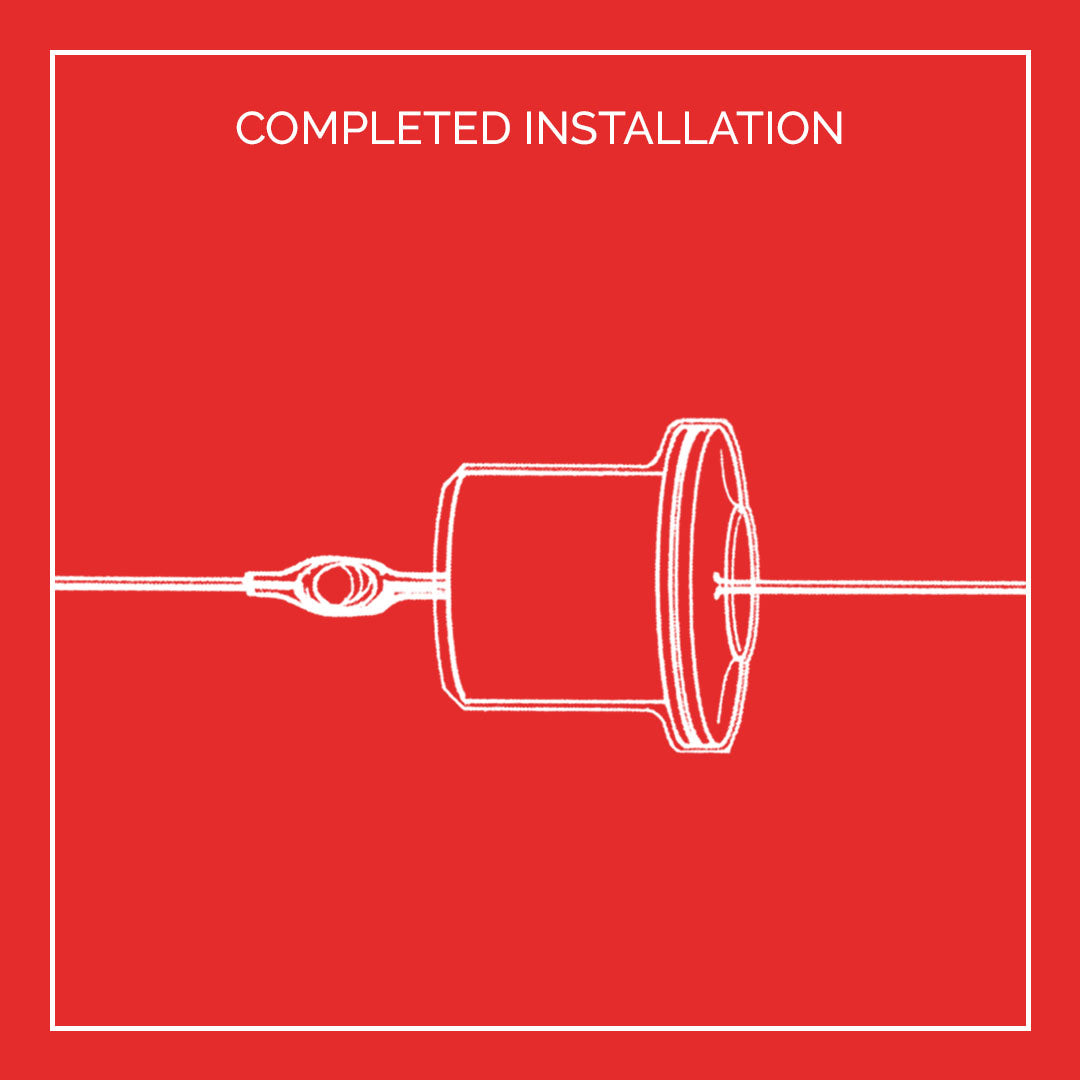

First, determine the tubing size required. For example, Fluorostore currently stocks several sizes of FEP 1:3 heat shrink tubing. Select an "as supplied I.D" sufficient to slip over the object you want protected, and having an "after shrinkage I.D" smaller than the smallest part of the protected object. Generally, the tubing should be cut 4 to 10% longer than the overall length of the object (to compensate for axial shrinkage). Allow for sufficient additional length to compensate for any variations in the contour of the object's surface. After shrinking, trim the excess length with a sharp knife or razor-blade.

How to "shrink" tubing over the protected component

Heat-shrink tubing can be shrunk in an oven or by means of a portable hot-air gun.

An oven may be an effective way to quickly apply a uniform amount of heat over the tubing and protected component. The oven simply needs to raise the temperature of the tubing higher than its "shrink" temperature. When using an oven, keep these tips in mind:

- Parts should be suspended or supported without touching the walls or plates of the oven

- With small parts, a fast cycle (into a hot oven and out quickly) may be used to shrink tubing without overheating the protected component

A heat gun a convenient way to shrink tubing when an oven is not available. Typically, parts are covered one at a time or in small batches. Heat guns are particularly effective for shrinking roll covers. When using a heat gun, here are some tips to keep in mind:

- Rotate the part while heat is being applied or use baffles to distribute the heat uniformly around the tubing

- For larger parts, heat distribution can be improved by assembling baffles of sheet metal to direct and distribute heat uniformly

Contact Fluorostore today at support@fluorostore to find out more about our heat-shrink tubing products.