The benefits of fluoropolymer shell and tube heat exchangers

Fluorotherm offers a range of shell and tube heat exchangers. But what do they actually do, and what sets them apart from the rest?

The purpose of shell and tube heat exchangers is to transfer heat from one fluid to another. They are commonly used across a wide range of industries, including chemical processing, power generation, oil and gas, and HVAC.

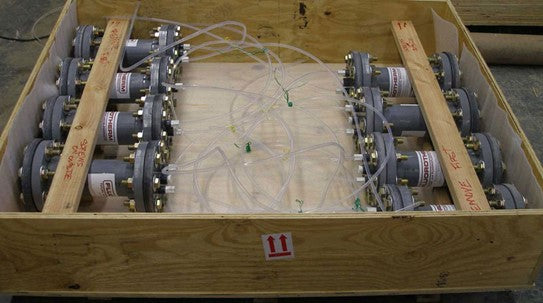

Fluorotherm’s shell and tube heat exchangers are specially designed using expertly manufactured fluoropolymers in order to provide targeted and effective heat transfer for corrosive and ultrapure substances. Their durable design means that they are easy to maintain, making them ideal for large enterprises.

Fluid Transfer

Shell and tube heat exchangers are devices used to transfer heat between two or more fluids that sit at different temperatures. The heat exchanger consists of a series of tubes that are enclosed within a shell. The two fluids flow through the tubes inside the shell, then the heat is transferred from one fluid to the other through the walls of the tubes.

How They Work

These exchangers work by allowing the primary fluid to flow through the tubes, while the secondary fluid flows through the outer surrounding shell. Heat is transferred from the hotter fluid to the cooler fluid through the tube walls, which are usually made of metals like copper or stainless steel.

The fluids are kept separate in order to prevent mixing, and they typically flow in opposite directions to maximize the efficiency of heat transfer.

Product Benefits

The professionals at Fluorotherm explain that the fluid flowing through a tube pathway passes through an ultrapure fluoropolymer material. The use of this chemically inert composition means that there is no risk of chemical reaction or impurities occuring throughout the process, making their shell and tube heat exchangers perfect for those working with any corrosive or ultrapure materials.

After use, the heat exchangers can be fully purged and readied for new projects, thanks to the unidirectional shell and tubing. This not only assists in keeping the tubes uncontaminated, but also makes them ideal for continuous or batch operations.

Depending upon the type of work being performed, there may be different requirements when it comes to the ideal surface area during heat transfer. These products range everywhere from one square foot of coverage to over 100 square feet - depending on the client’s needs.

Designed for durability, the tubes can be easily taken apart to allow for inspection, cleaning, or repairs.

Materials

The shells of these heat exchangers are made with PVC, CPVC, and PVDF. The tubing is comprised of either PTFE, FEP, PFA, or PVDF. However, Fluorotherm is constantly researching ways to improve their products to make them more stable and sustainable for specialist work, so these fluoropolymers may end up changing in upcoming iterations.

Heat Exchangers in Use

Shell and tube heat exchangers are perfect for use in laboratory settings, industrial applications, chemical processing, and HVAC. This includes use within pharmaceuticals, manufacturing, refrigeration, mining, chemical processes, oil refining, and more.

For those interested in integrating shell and tube heat exchangers into their project, feel free to reach out and speak with their experts to find out how they can assist.