A 5-step guide to covering electronic leads with fluoropolymer tubing

When it comes to protecting electronic leads, one of the most effective methods is to cover them with fluoropolymer tubing. This specialized tubing provides excellent insulation and resistance to heat, chemicals, and electrical currents. In this blog post, we will provide you with a step-by-step guide on how to cover electronic leads with fluoropolymer tubing, along with a real-life case study to illustrate its effectiveness.

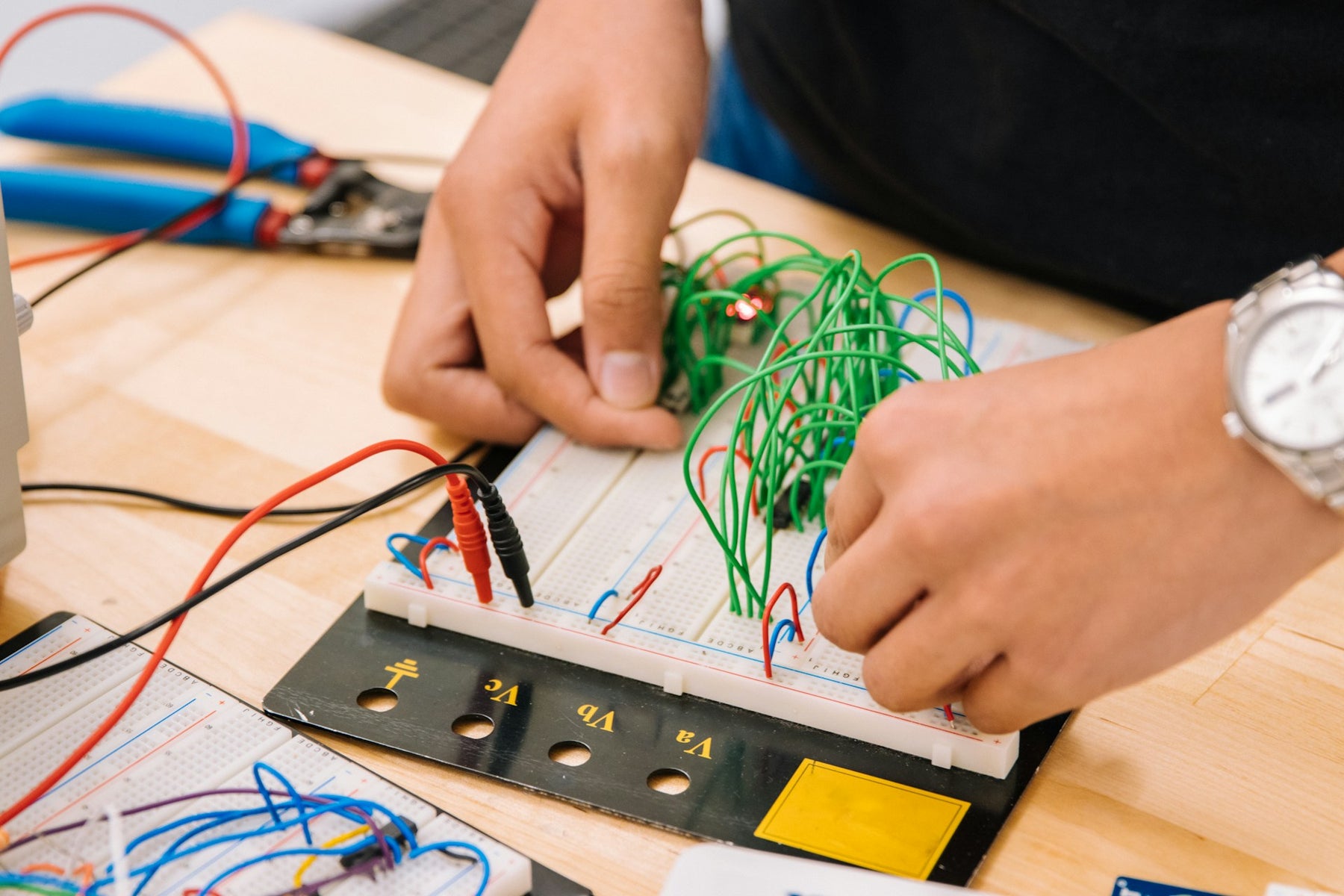

Step 1: Gather the necessary materials

Before you begin, make sure you have all the materials you need. This includes fluoropolymer tubing, a heat gun, a cutting tool, and heat shrink tubing. It's important to choose the right size of fluoropolymer tubing that will fit snugly over your electronic leads.

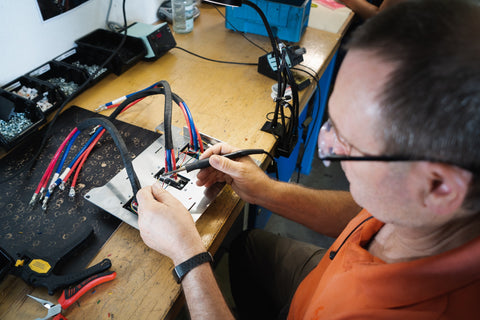

Step 2: Prepare the electronic leads

Start by cleaning the electronic leads to ensure there is no dirt or debris that could interfere with the tubing. Then, cut the fluoropolymer tubing to the desired length, making sure it is slightly longer than the leads to allow for shrinkage.

Step 3: Slide the tubing over the leads

Next, carefully slide the fluoropolymer tubing over the electronic leads. Make sure it covers the entire length of the leads and leaves no exposed areas. The tubing should fit snugly but not be too tight, as this could cause damage to the leads.

Step 4: Apply heat

Using a heat gun, apply heat evenly to the fluoropolymer tubing. This will cause the tubing to shrink and form a tight seal around the electronic leads. Be careful not to overheat the tubing, as this could lead to melting or damage.

Step 5: Secure with heat shrink tubing

For added protection and stability, you can secure the ends of the fluoropolymer tubing with heat shrink tubing. Simply slide the heat shrink tubing over the ends of the tubing and apply heat to shrink it into place. This will ensure a secure and durable covering for your electronic leads.

Benefits: Increased reliability and lifespan

A company specializing in electronic manufacturing implemented this method to protect their sensitive leads from environmental factors and mechanical stress. As a result, they experienced a significant increase in the reliability and lifespan of their electronic components. The fluoropolymer tubing provided superior insulation, preventing short circuits and damage caused by moisture or chemicals. Additionally, the tubing's resistance to heat and electrical currents ensured the leads remained protected even in demanding operating conditions.

Covering electronic leads with fluoropolymer tubing is a reliable and effective method to protect your electronic components. By following the 5-step guide outlined in this blog post, you can ensure the longevity and performance of your electronic leads. Don't underestimate the importance of proper insulation and protection – it can make all the difference in the reliability and lifespan of your electronic devices.