The benefits of fluoropolymer tubing in emissions testing

Emissions testing is a critical process that helps ensure compliance with environmental regulations and standards. It involves measuring the pollutants emitted by vehicles, industrial equipment, and other sources. To accurately measure these emissions, reliable and durable tubing is essential. This is where fluoropolymer tubing comes into play.

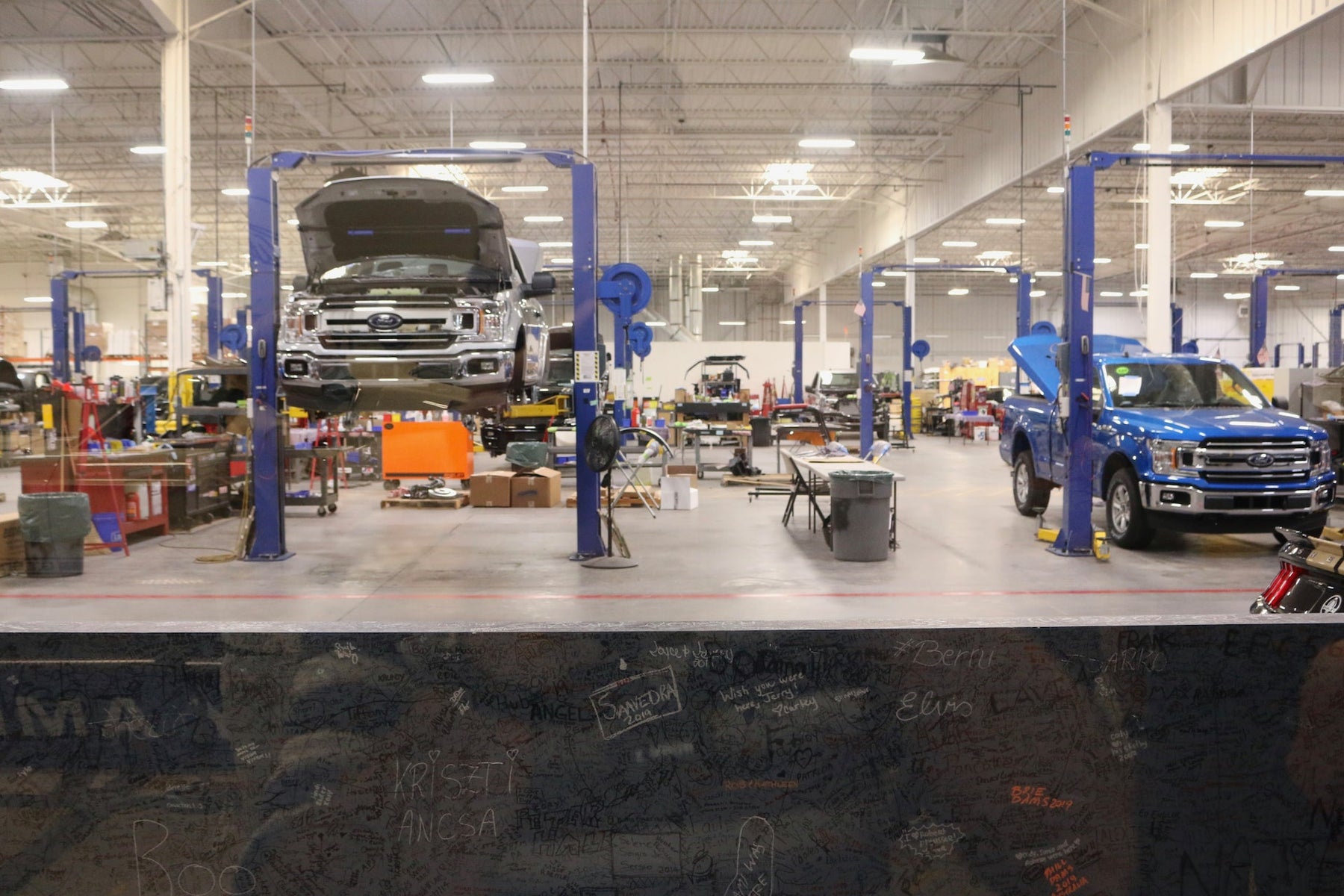

In emissions testing, fluoropolymer tubing is used to transport exhaust gases from the source to the measuring instruments.

There are several key benefits of using fluoropolymer tubing in emissions testing:

Chemical resistance

Fluoropolymer tubing has excellent chemical resistance, which is crucial in emissions testing where the tubing comes into contact with corrosive exhaust gases. It can withstand exposure to a wide range of chemicals, including acids, bases, and solvents, without degrading or compromising its performance.

High temperature resistance

Emissions testing involves handling hot exhaust gases, which can reach high temperatures. Fluoropolymer tubing can withstand extreme temperatures, ensuring that it does not melt, deform, or release any harmful substances into the environment. This high temperature resistance contributes to the accuracy and reliability of emissions measurements.

Low friction

Fluoropolymer tubing has a low coefficient of friction, meaning that it offers minimal resistance to the flow of gases. This property allows for smooth and efficient transport of exhaust gases, reducing pressure drops and ensuring accurate measurements. It also helps prevent the buildup of contaminants and particulate matter inside the tubing, minimizing the risk of clogging or blockages.

Durability

Fluoropolymer tubing is highly durable and long-lasting. It can withstand the rigors of emissions testing, including exposure to harsh chemicals, high temperatures, and mechanical stress. Its durability ensures that the tubing remains intact and functional over an extended period, reducing the need for frequent replacements and minimizing downtime.

Versatility

Fluoropolymer tubing is available in various sizes, configurations, and lengths, making it suitable for different emissions testing setups. It can be easily customized to meet specific requirements, ensuring optimal performance and compatibility with the measuring instruments and equipment used in the testing process.

In conclusion, fluoropolymer tubing offers numerous benefits in emissions testing. Its chemical resistance, high temperature resistance, low friction, durability, and versatility make it an excellent choice for transporting exhaust gases and ensuring accurate emissions measurements. By using fluoropolymer tubing, emissions testing facilities can enhance their efficiency, reliability, and compliance with environmental regulations.