Heat Shrink Tubing's Ease of Use and Versatility Make It An All-Around Asset

There’s no excuse for exposed conduits. The tubing that’s used for fluid flow, saturated steam or electrical wire insulation is selected because it can get the job done while withstanding the elements. Part of this equation is heat shrink tubing, which can protect the materials it is designed to wrap around. If you’ve ever spliced and joined electrical wires, you know that applying heat shrink tubes is the crucial final step after soldering your connections. The same concept is at play here – only in a large-scale industrial application. There are many considerations that a company must make when selecting the right heat shrink tubing for their job. It’s up to companies like Fluorotherm to educate readers and guide them toward the correct decision for their unique needs.

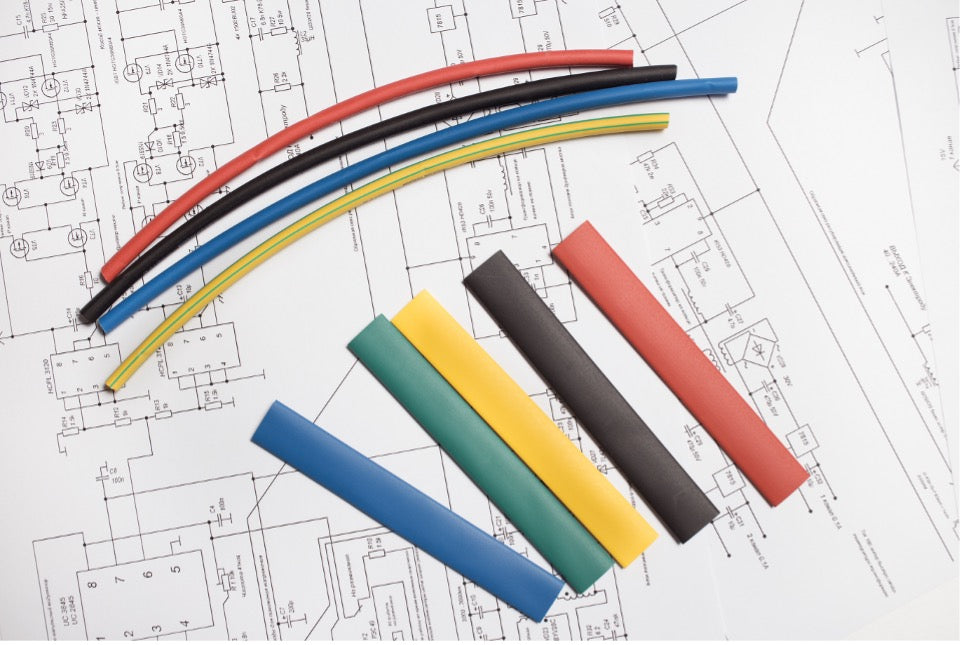

FEP tubing, as opposed to the more well-known PTFE products, boasts transparency, stiffness, a higher working pressure and ability to be used in temperatures approximately 50 degrees Fahrenheit lower. The heat shrink tubing offered by Fluorotherm is designed with FEP tubing in mind, which gives fit and performance a boost over other products. This type of tubing provides a protective jacket over conduit tubes, but that’s just one application. Heat shrink tubing can also be used as a cover on temperature probes and heat exchangers; an anti-fouling barrier on paint, food and chemical equipment; shields and insulation for electrical insulation; as protection from abrasion on hydraulic hoses or even something as straightforward as a chafing sleeve or means of identification.

There are some recommended practices when it comes to usage, which Fluorotherm wants to bring to the attention of readers and companies considering the product. Selecting the correct size of tubing is generally done by assessing the dimensions of the object that’s going to be covered. The rule of thumb suggested here is that the FEP tubing, in its pre-shrunk state, should be no more than 10 percent longer than the object it will cover. An added benefit to using this product is that any overhang can simply be trimmed with a knife. Application can be straightforward, as well, with a heat gun being used to deliver uniform shrinkage of individual parts.

The broad applications of heat shrink tubing in industries as varied as electronics to food service gives this product a wide appeal. Something as simple as cable management can be accomplished with this product while aerospace companies can also complete projects are critical infrastructure. There are unexpected issues just waiting to be solved by heat shrink tubing and Fluorotherm will continue to deliver those solutions.